The electric induction furnace is a kind of melting furnace that uses electric streams to liquefy metal. Induction furnace are perfect for liquefying and alloying a wide assortment of metals with least soften misfortunes, be that as it may, small refining of the metal is conceivable.

The principle of induction heating is mainly based on two phenomena:

1. Electromagnetic induction

2. The Joule effect

The principle of induction heating is mainly based on two phenomena:

1. Electromagnetic induction

2. The Joule effect

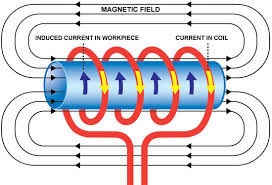

1) ELECTROMAGNETIC INDUCTION :

The transfer of energy to the object to be heated occurs by method of electromagnetic induction. Any electrically conductive material put in a variable attractive field is the site of induced electric current.

The transfer of energy to the object to be heated occurs by method of electromagnetic induction. Any electrically conductive material put in a variable attractive field is the site of induced electric current.

2) JOULE HEATING :

Joule heating, also known as ohmic heating and resistive heating, is the process by which the passage of an electric current through a conductor releases heat. The heat produced is proportional to the square of the current multiplied by the electrical resistance of the wire.

Star Point :

Induction heating depends on the one of a kind qualities of radio frequency (RF)energy that divide of the electromagnetic range underneath infrared and microwave energy.

Since heat is exchanged to the item by means of electromagnetic waves, the part never

comes into direct contact with any fire, the inductor itself does not get hot and there is no item tainting. Induction heating is a quick, clean, non-contaminating heating.

The induction coil is cool to the touch; the heat that develops in the coil is always

cooled with flowing water.

Stead Fast Engineers Pvt Ltd is an engineering company engaged in designing and manufacturing of Induction Melting furnaces, Induction Heater and Lining Machines for Foundries Steel Plants and Forging Plants. http://www.steadfastengg.com/

No comments:

Post a Comment