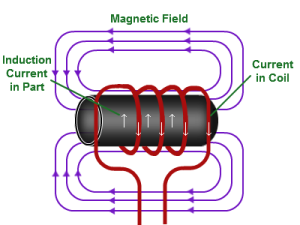

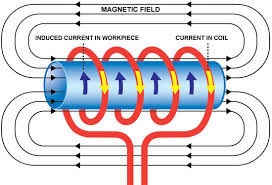

The principle of induction melting is that a high voltage electrical supply from a primary induces a low voltage, high current within the metal, or secondary. heating is just a technique of transferring heat.

Induction furnaces square measure ideal for softening and alloying a large style of metals with minimum melt losses, however, very little purification of the metal is feasible.

There are two main types of induction furnace :

1. Coreless

2. Channel

Coreless Induction Furnaces :

The heart of the coreless induction furnace is that the coil, that consists of a hollow section of significant duty, high physical phenomenon copper tube that is wound into a turbinate coil. Coil form is contained inside a steel shell and magnetic shielding is employed to forestall heating of the supporting shell. to safeguard it from warming, the coil is cool, the water bing recirculated and cooled during a cooling. The shell is supported on trunnions on that the furnace tils to facilitate running.

The vessel is created by ramming a granular refractory between the coil and a hollow internal former that is liquified away with the primary heat feat a mold lining.

The power cubmicle converts the voltage and frequency of main offer, ot that needed for electrical melting. Frequencies utilized in induction melting vary from fifty cycles per second (mains frequency) to ten,000 cycles per second (high frequency). the upper the operational frequency, the bigger the most quantity of power which will be applied to a chamber of given capability and also the lower the quantity of turbulence elicited.

When the charge material is liquified, the interaction of the magnetic flux and also the electrical currents flowing within the coil manufacture a stirring action inside the liquified metal. This stirring action forces the liquified metal to rise upwards within the centre inflicting the characteristic gristle on the surface of the metal. The degree of stirring action is influenced by the ability and frequency applied further because the size and form of the coil and also the density and viscousness of the liquified metal. The stirring action inside the tub is vital because it helps with combination of alloys and melting of turnings further as homogenising of temperature throughout the chamber. Excessive stirring will increase gas obtain, lining wear and oxidisation of alloys.

The coreless induction chamber has for the most part replaced the vessel chamber, particularly for melting of high temperature alloys. The coreless induction chamber is often wont to soften all grades of steels and irons further as several non-ferrous alloys. The chamber smart} for remelting and alloying attributable to the high degree of management over temperature and chemistry whereas the induction current provides good circulation of the soften.

Channel Induction Furnaces :

The channel induction chamber consists of a refractory lined steel shell that contains the liquified metal. connected to the steel shell and connected by a throat is an induction unit that forms the melting part of the chamber. The induction unit consists of AN iron core within the variety of a hoop around that a primary coil is wound. This assembly forms an easy electrical device within which the liquified metal loops includes the secondary part. the warmth generated inside the loop causes the metal to flow into into the most well of the chamber. The circulation of the liquified metal effects a helpful stirring action within the soften.

Channel induction furnaces square measure usually used for melting low temperature alloys and or as a holding and superheating unit for higher temperature alloys like forged iron. Channel induction furnaces are often used as holders for metal molten off peak in coreless induction induction units thereby reducing total melting prices by avoiding peak demand charges.

Stead Fast Engineers provide world class induction heating and melting solutions .Stead Fast Engineers manufactures world class induction melting furnaces under the brand name 'STEFEN'.

STEFEN Quick melt and Smart melt furnaces are designed to increase the customer’s profitability and improve his market credibility by minimizing down time.

visit products and services : http://www.steadfastengg.com/induction-melting-solutions.php